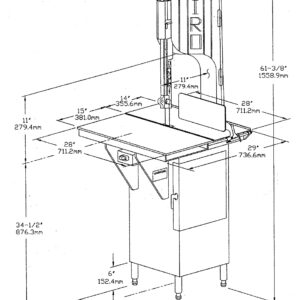

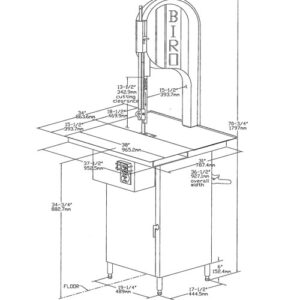

| DIMENSIONS | W: 21.2″, L: 37″, H: 23.6″ |

|---|---|

| PHASE | 1 |

| VOLTAGE | 220 |

| WATTAGE | 2250 |

| 1ST GRINDING CAPACITY | 55 lb/min |

| 2ND GRINDING CAPACITY | 29 lb/min |

| HORSEPOWER | 3 |

| HUB SIZE | 32 |

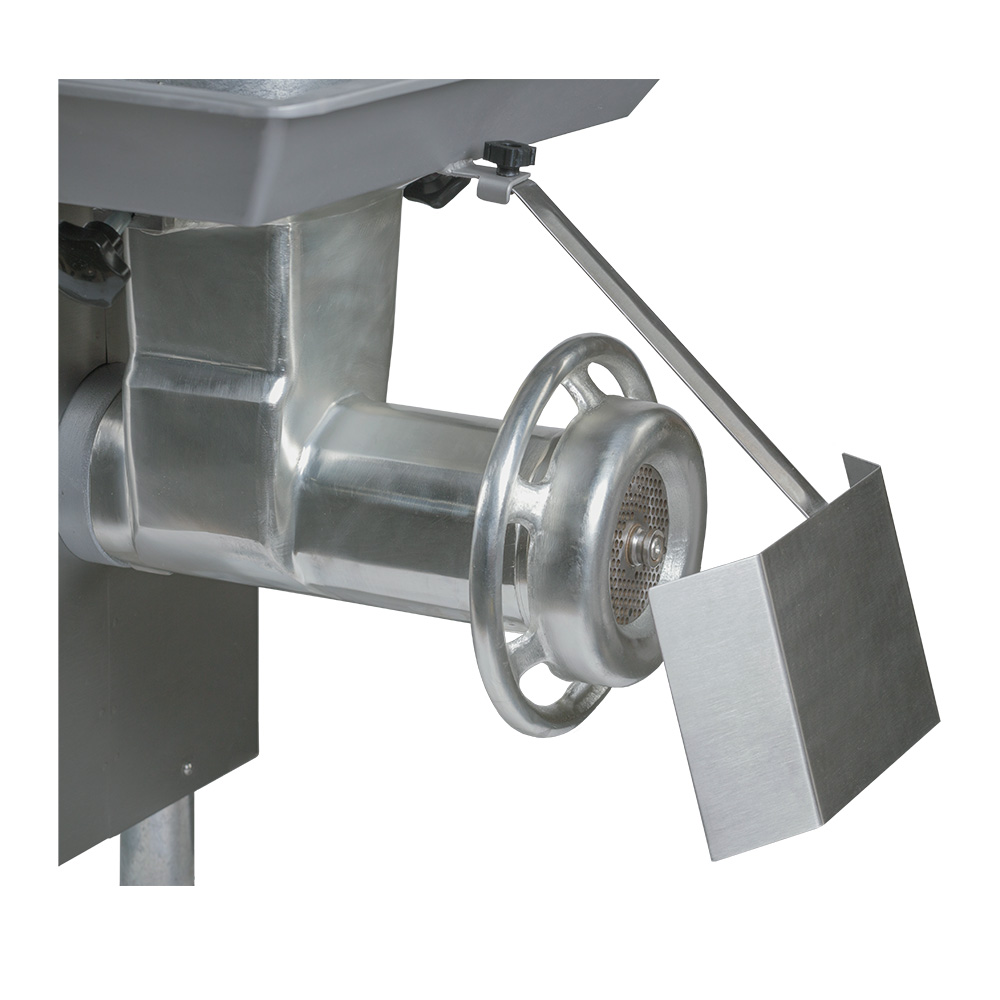

#32 SINGLE PHASE MEAT GRINDER

- Heavy duty grinder with 3,300+ lb/hr. first grinding capacity.

- 220 volts/single phase electrical connection.

- Powerful 3 HP motor grinds through all types of meats.

- Designed with a robust headstock and permanently affixed safety guard.

- Food-grade stainless steel body and large feed tray.

Reviews

There are no reviews yet.